August 25, 2015 weblog

Made faster, costing less, robotic hand wins Dyson award

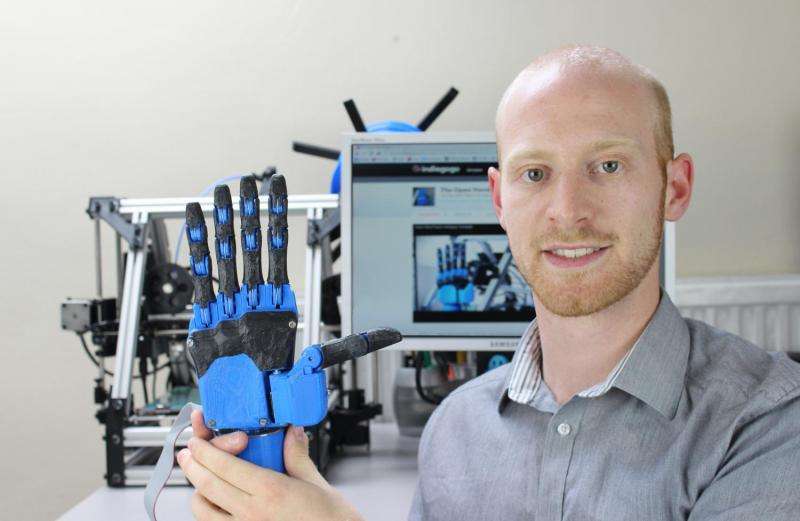

The Open Bionics robotic hand for amputees, a prototype, has won the Dyson Award UK engineering prize. The hand now has the chance to compete for the international title. The Engineer referred to this winner of "the UK leg of the James Dyson Award, an annual prize established by the prominent industrialist's charitable trust, The James Dyson foundation."

According to the BBC's Leo Kelion, the creator of the Open Bionics project, Joel Gibbard, said he can 3D-scan an amputee and build that person a custom-fitted socket and hand in less than two days. This is significant in contrast to other companies' models which can take months if not weeks to make.

The inventor said he could "size up a user in a matter of minutes using a tablet equipped with a special sensor, 3D-print the parts in about 40 hours, and finally fit them together in a further two hours."

Another highlight of this 3D printed hand is that it is an affordable prosthetic. Speaking to a reporter, Open Bionics programmer Olly McBride said that other companies' models with controllable fingers were far costlier; this version was $3,000 or less.

Kelion said the ones with controllable fingers are usually sold for between £20,000 and £60,000. The cost factor is especially burdensome for children, whose prosthetics need to be changed once or even twice a year to accommodate growth.

Kelion said the Open Bionics inventor intended to charge customers £2,000 for the device, including the cost of a fitting.

Testing is ongoing. Joel Gibbard, CEO, said in the BBC report that "we are testing it with users and household objects and trying to come to a compromise that means it is very affordable and still has enough power to do most of the stuff that people want."

The BBC quoted Barbara Jemec, founding chair of the British Foundation for International Reconstructive Surgery and Training (BFirst), remarking on news of the prize. "Amputees, especially in developing countries, such as Sierra Leone where the civil war left many upper limb amputees, need to have access to affordable and durable prosthetics that work."

James Dyson was quoted in The Engineer: "It shows how bold ideas don't need a big budget and if successful his technology will improve lives around the world."

Kelion noted the project was open source where anyone can share and use the designs without charge so long as they share any improvements they make.

Gibbard told the BBC the device was a skeleton with a "skin" on top. The newest iteration is made of thermoplastic elastomer, a flexible plastic.

Wired.co.uk further detailed that the design is biomimetic. The soft robotics closely replicate the hand's bones, ligaments and skin. "This helps keeps the weight of the prosthesis down while also making it more stable."

The hand can detect muscle movements and sensors built into the digits help users manage the limits of pressure to exert and to control grip. Possible movements include opening and closing the fingers and forming a pinch grip.

© 2015 Tech Xplore